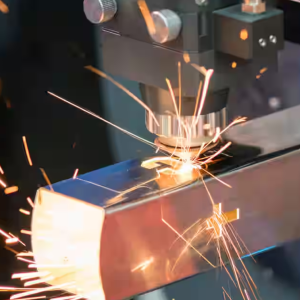

In today’s rapidly evolving manufacturing landscape, laser cutting services have emerged as a game-changing technology that’s revolutionizing how we approach precision manufacturing. Whether you’re an industry veteran or new to the world of fabrication, understanding the transformative potential of modern laser cutting services can give your business a significant competitive edge.

The journey of laser cutting services from a nascent technology to an industry standard is nothing short of remarkable. Today’s laser cutting combine unprecedented precision with efficiency, making them indispensable across various industries. From automotive parts to architectural elements, these advanced laser cutting services are setting new benchmarks in manufacturing excellence.

The adoption of professional laser cutting services continues to accelerate, and for good reason. These cutting-edge solutions offer unmatched advantages that traditional cutting methods simply can’t match. Modern laser cutting services provide exceptional edge quality, minimal material waste, and the ability to handle complex geometries with remarkable accuracy.

When it comes to precision manufacturing, laser cutting services stand in a league of their own. The technology employs focused laser beams that can achieve tolerances as tight as ±0.1mm, making these laser cutting services ideal for projects requiring extreme accuracy. This level of precision ensures that every cut meets exact specifications, reducing waste and improving overall product quality.

While the initial investment in laser cutting services might seem substantial, the long-term cost benefits are undeniable. Advanced laser cutting services significantly reduce material waste, minimize the need for secondary operations, and increase production efficiency. These factors combine to make laser cutting a cost-effective solution for businesses of all sizes.

The versatility of modern laser cutting has led to their adoption across numerous sectors:

In the automotive industry, laser cutting play a crucial role in producing everything from body panels to intricate interior components. The precision offered by these laser cutting services ensures perfect fits and optimal performance of manufactured parts.

Aerospace manufacturers rely heavily on laser cutting services for creating complex components that must meet stringent safety and performance standards. The consistency and accuracy of professional laser cutting make them ideal for producing critical aerospace parts.

Modern architecture benefits tremendously from laser cutting, particularly in creating decorative elements and structural components. These laser cutting services enable architects to bring their most innovative designs to life with unprecedented accuracy.

Understanding the technology powering modern laser cutting services helps appreciate their capabilities. Today’s laser cutting services utilize various types of lasers, including:

CO2 Laser Systems: CO2 laser cutting services excel at processing non-metallic materials and are widely used in the textile and wood processing industries. These laser cutting services offer exceptional versatility and cost-effectiveness for many applications.

Fiber Laser Technology: The latest fiber laser cuttings represent the cutting edge in metal processing. These advanced laser cutting services deliver higher speeds and greater energy efficiency, making them ideal for high-volume metal fabrication projects.

To get the most out of laser cutting services, consider these key factors:

Material Selection: Different materials respond differently to laser cutting services. Understanding which materials work best with specific types of laser cutting services ensures optimal results. Professional providers can guide you in selecting the most appropriate laser cutting services for your particular material and application.

Design Optimization: While laser cutting offer remarkable flexibility, optimizing designs for these processes can further enhance results. Working closely with experienced laser cutting services providers helps ensure your designs take full advantage of the technology’s capabilities.

As technology continues to evolve, laser cuttings are becoming increasingly sophisticated. The integration of artificial intelligence and machine learning with laser cutting services is opening new possibilities for automation and precision manufacturing.

Sustainability in Manufacturing: Modern laser cutting services contribute significantly to sustainable manufacturing practices. The precision and efficiency of these laser cutting services result in minimal material waste and reduced energy consumption, aligning with growing environmental concerns in industry.

Selecting the appropriate laser cutting services partner is crucial for success. Look for providers who offer:

The impact of laser cutting services on modern manufacturing cannot be overstated. As industries continue to evolve, the role of advanced laser cutting services in shaping the future of manufacturing becomes increasingly significant. By partnering with experienced laser cutting services providers, businesses can leverage this powerful technology to achieve their manufacturing goals efficiently and cost-effectively.

Whether you’re looking to improve production efficiency, reduce costs, or enhance product quality, professional laser cutting services offer solutions that can transform your manufacturing processes. The key lies in understanding the technology’s capabilities and working with experienced providers who can deliver the precise laser cutting services your projects demand.